Products

- Capacitor Networks, Arrays(2073)

- Aluminum Electrolytic Capacitors(119232)

- Tantalum Capacitors(106098)

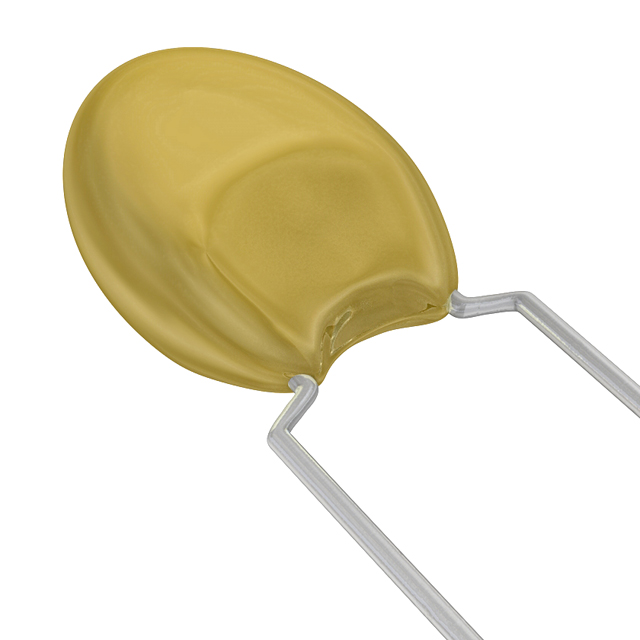

- Ceramic Capacitors(802073)

- Electric Double Layer Capacitors (EDLC), Supercapacitors(2508)

- Film Capacitors(165215)

- Mica and PTFE Capacitors(9477)

- Trimmers, Variable Capacitors(1755)

- Thin Film Capacitors(3401)

- Niobium Oxide Capacitors(219)

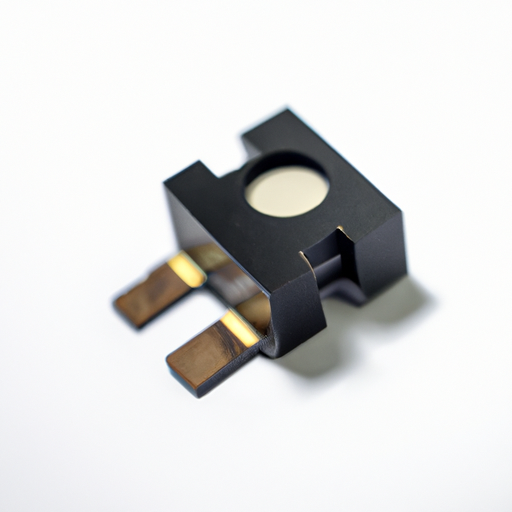

PMDM

PMDM

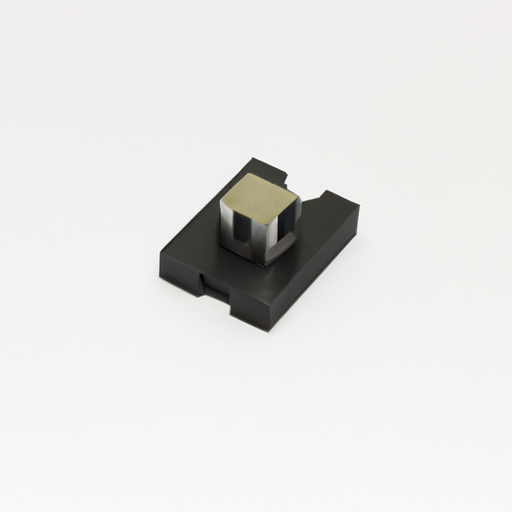

YAGEO

YAGEO

EMIT

EMIT

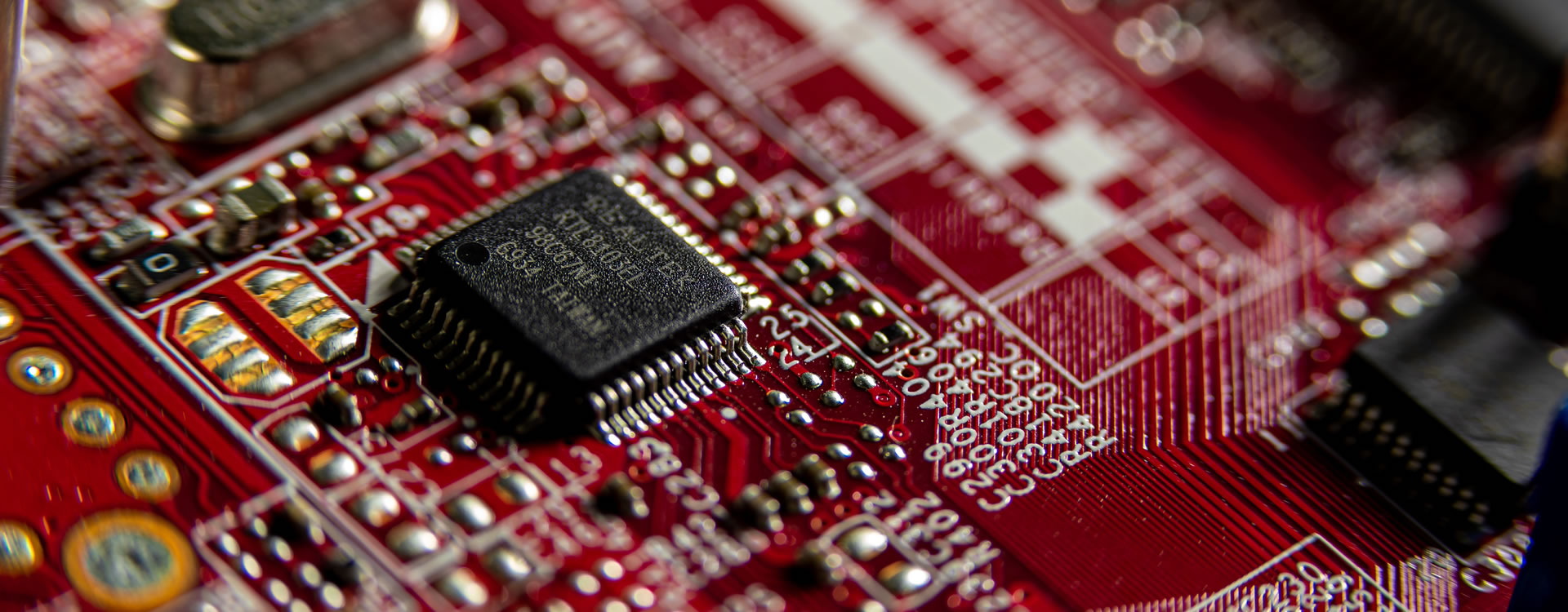

TE Connectivity AMP Connectors

TE Connectivity AMP Connectors

Wickmann / Littelfuse

Wickmann / Littelfuse

3M

3M

Intersil (Renesas Electronics Corporation)

Intersil (Renesas Electronics Corporation)

B&K Precision

B&K Precision

Comair Rotron

Comair Rotron

Hirose Electric Co., Ltd.

Hirose Electric Co., Ltd.